Buntingford Air Tightness Testing Certified by AF-Acoustics

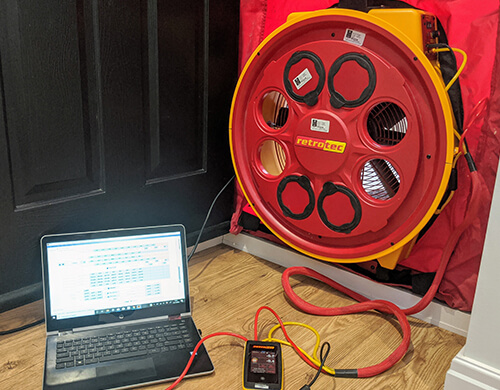

Air tightness testing determines the quantity of air coming out of cracks in a building. It is also known as air permeability testing or air leakage testing. Air tightness testing has been a compulsory part of the building regulations for new dwellings, renovations and commercial projects since the revision of Document L in 2006.