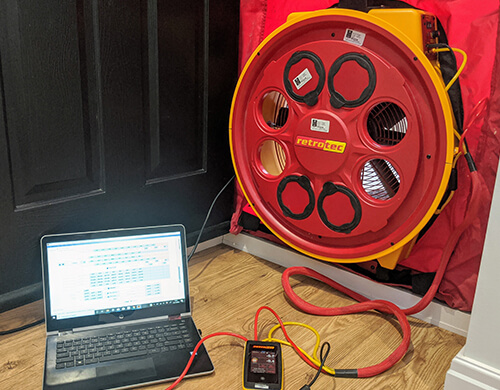

Air Tightness Testing, Certified by AF-Acoustics, in Spring-Grove

The measurement of air escaping from a building is called air tightness testing. It is also referred to as air permeability testing or air pressure testing. Air tightness testing became an integral part of building regulations for new buildings, commercial developments and revamped buildings in 2006 after Document L was reviewed.