Noise control is an approach to reduce noise pollution or to reduce the impact of that noise. Noise control can take many forms, from control of noise in a workplace to reduction of noise from extractor fans on restaurants. To create a healthier workplace, the American National Institute for Occupational Safety and Health (NIOSH) recommends an approach based on the hierarchy of control.

Noise Control

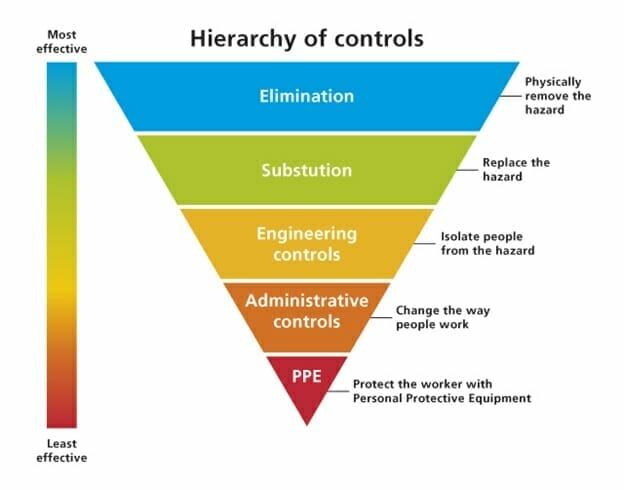

Hierarchy of Control

AF Acoustics use the hierarchy of control to determine how to implement practical and effective noise controls. This approach groups actions by their likely effectiveness in reducing or removing the noise hazard.

There are several ways in which noise can be controlled, which can vary from one workplace to another. Good understanding of plant operations and work processes is necessary to determine the most effective method of eliminating, minimising or controlling the noise.

Elimination

Elimination is the process that takes away the noise source, which is the most effective way to reduce noise.

Examples of noise elimination will include avoiding the use of noisy equipment or machinery and moving the noisy operations away from other work activities.

Advance planning and the introduction of a suitable purchasing or hire policy are essential to reducing the noise levels in a workplace. Consideration at an early stage about how the new work process or new machinery would work without exposing the workers to excessive noise is the most cost-effective and long-term measure businesses can take to reduce overall noise levels. The noise levels of new machinery should be considered before purchasing. The UK Health and Safety Executive’s ‘Buy Quiet’ guide for purchasing quieter equipment provides useful further advice.

Substitution

When elimination is not possible, substitution of equipment for quieter equipment may be the next best alternative to protect workers from hazardous noise.

Work processes and alternative equipment should always be considered, which would make the job less noisy. It is important to keep up-to-date with industry good practice and any applicable standards. Performing a task differently can also protect the workers from noise exposure – for example using electrical engines instead of petrol engines.

Engineering Controls

Engineering controls are about making changes to processes, machinery or equipment so that workers are exposed to less noise.

For example, using screens, barriers, enclosures and absorbent materials help to reduce workers’ noise exposure.

Administrative Controls

Administrative controls are the way work is organised to reduce either the number of workers who are exposed or the length of time they are exposed to noise. Administrative controls should be used when it is not possible to reduce noise exposure through elimination, substitution or engineering noise control measures. Administrative measures may include, clearly signposting noisy areas and setting up hearing protection zones, scheduling tasks so that they are preformed when as few people as possible are present, or performing noisy tasks away from others.

Personal protective equipment

Personal protective equipment (PPE), such as ear defenders or other hearing protection devices, is the last option in the hierarchy of control and should be used as a last resort after all efforts to eliminate or reduce the noise levels have been exhausted through technical and organisational means.

All hearing protection must be capable of reducing the noise exposure to the safe exposure levels and should be made available for workers to use. It is important to make sure that the hearing protection chosen to protect the workers is suitable for individuals’ working environment and compatible with other personal protective equipment being used, for example hard hats, dust masks, eye protection etc.